Consult Us

(+86)18168891000

Core Advantage

Customized AGV Robots: Empowering Enterprise Automation, Driving Cost Reduction & Efficiency Gains

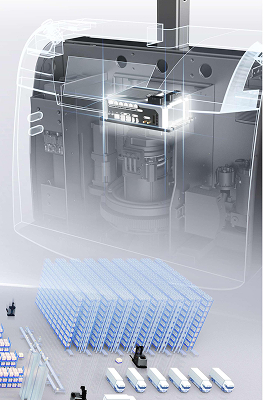

Smart System

Autonomous navigation+intelligent obstacle avoidance+multi machine collaboration, even complex production lines can accurately respond to instructions

About AGV

We Provide the Best Service for the Modern industrial logistics

Modular design ensures the reliability and stability of the product, while significantly reducing maintenance costs, saving you a lot of time and money.

Flexible services

Ready to use and flexible deployment, with routes adjusted in real-time according to business needs, suitable for 99% of industrial scenarios

Sustainability

Build Quality

Technology

Choose us

Redefine mobile robots

Millimeter-precision intelligent material handling, coordinated fleet management of hundreds of AGVs, industrial-grade safety protection.

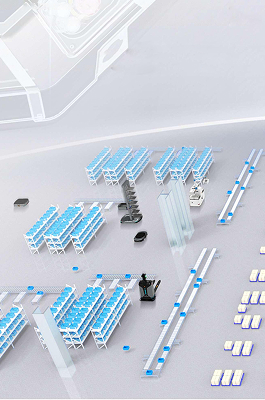

Who We Are

The One Stop Solution for Your Industries

Through on-site surveys and scenario simulations, precisely match the appropriate solution. The solution design covers AGV selection, path planning, and system integration, ensuring the technical feasibility of the solution.Continuously optimize the use of big data analytics to dynamically improve operational efficiency and provide customers with comprehensive solution support.

- Needs Assessment

- Solution Design

- Deployment Implementation

- Continuous Optimization

Leader in One-Stop AGV Solutions

Our Services

The Best System Services

We turn your unique operational needs into a precision-engineered system. Whether you require adjusted lifting heights for specialized material racks, custom navigation logic for irregularly shaped workspaces, or tailored fleet scheduling rules aligned with your production beats, our Latent Lifting AGV adapts perfectly to your site, processes, and goals.

Technological Leadership

Dynamic compensation algorithm: automatic correction of ground vibration and temperature difference deformation, stable positioning accuracy of ± 2mm

Full-stack delivery

One-stop delivery of hardware + software + services, shortening the cycle time by 40%. Modular design: quick replacement of chassis, sensors, and vehicles without the need for reprogramming.

Industrial-grade security

Adapts to complex environments, provides real-time energy consumption monitoring under heavy load, and automatically switches to a safe path upon anomaly detection.

Flexible customization

Support deep customization of navigation modes, vehicle forms, and interface protocols to seamlessly integrate with mainstream global systems, breaking down data silos

Service Commitment

24/7 response time; Not only delivering equipment, but also ensuring continuous iteration and upgrading throughout the entire lifecycle: free software function updates, hardware support for trade in

Manufacture System

Material distribution for automotive assembly lines

Warehouse logistics

Intelligent sorting and stereo library docking

Machine Maintenance

Aseptic and precise transportation in clean workshops

3C Electronics

Chip/screen micro vibration suppression handling